We are committed to our clients. We have the best professionals and we handle all phases of new projects.

ASSISTANCE IN THE DESIGN OF A PART

The technical department provides customers with advice from the very beginning. We offer an overview of the process in order to obtain s successful result. We begin with designing the part together that will be modified according to the customer’s needs.

When applying design knowledge, it is important to consider the transformation process, the operation of the injection molds and the raw materials to be used depending on the final destination and intended use of the part.

BUILDING THE MOLD

We handle the mold by actively working along qualified and specialized mold suppliers. We constantly monitor the manufacturing process, offering all kind of advice and solutions to achieve the desired product. MAHER is responsible for monitoring and performing mold testing, and submitting samples until the final approval.

Once the process has been completed, we keep the molds in our facilities in proper working conditions and ensure fast response and service to meet customers’ needs and cover any unexpected event that may arise.

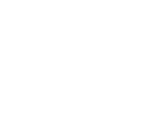

INJECTION AND TESTING

Once the mold is ready, we proceed with all tests to obtain the required specifications and the desired geometry.

We have the most modern machinery to guarantee a correct manufacture from the simplest to the most technically complex part, regardless of the shape, size or colour.

FINISHING AND ASSEMBLY

Depending on the nature of the parts, and if required by the client, the process is completed with a comprehensive service including finishing, assembly and packaging of the product.

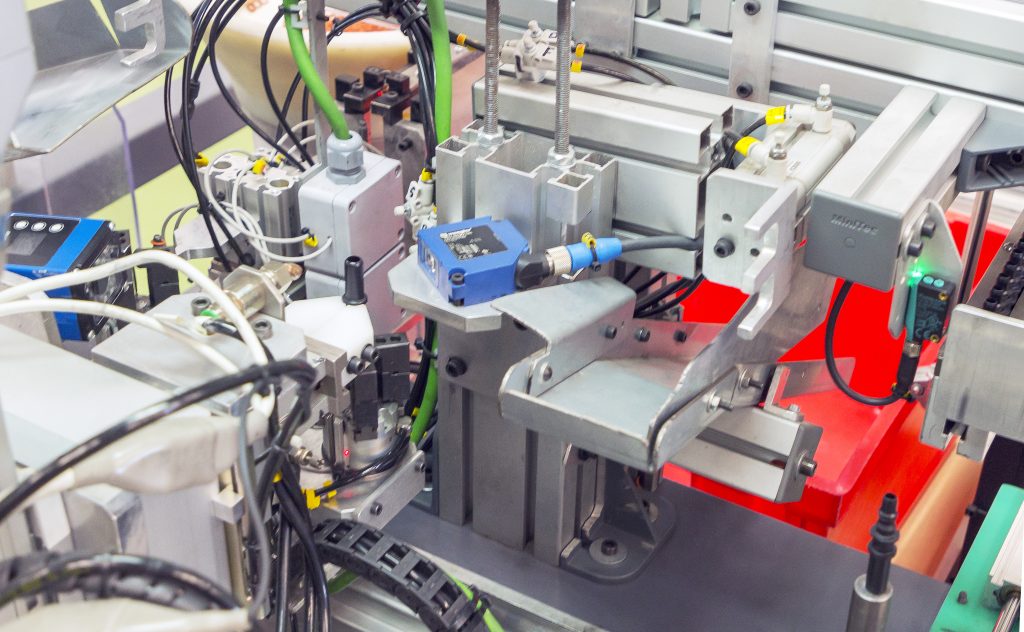

O-RING INSERTION

We have different assembly stations for o-ring insertion, automatic and manual, adapted to any geometry.

Our specialized equipment and the latest technology offer the highest quality final product, without intermediaries, offering parts with o-rings inserted and checked.

ULTRASONIC WELDING

The company has an ultrasonic welding machine adapted to our customer’s product.

Latest technology adapted exclusively for our customers and their products.

Maher has a technical and human team trained to the highest level that has been adapting to new demands, capable of competing in the most demanding market in terms of quality, service and manufacturing.

Maher has a technical and human team trained to the highest level that has been adapting to new demands, capable of competing in the most demanding market in terms of quality, service and manufacturing.

SPECIALISTS IN THE MANUFACTURE OF PARTS FOR THE AUTOMOTIVE SECTOR

LARGE VARIETY OF PRODUCTS, WITH DIFFERENT GEOMETRIES AND SPECIFICATIONS

HIGH PRECISION PARTS, HIGH TECHNICAL AND QUALITY REQUIREMENTS